CUSTOMER

The client is an enterprise that supplies and manufactures industrial and auxiliary equipment for automobile manufacturing and assembly corporations in Vietnam.

PROFESSIONAL REQUIREMENTS

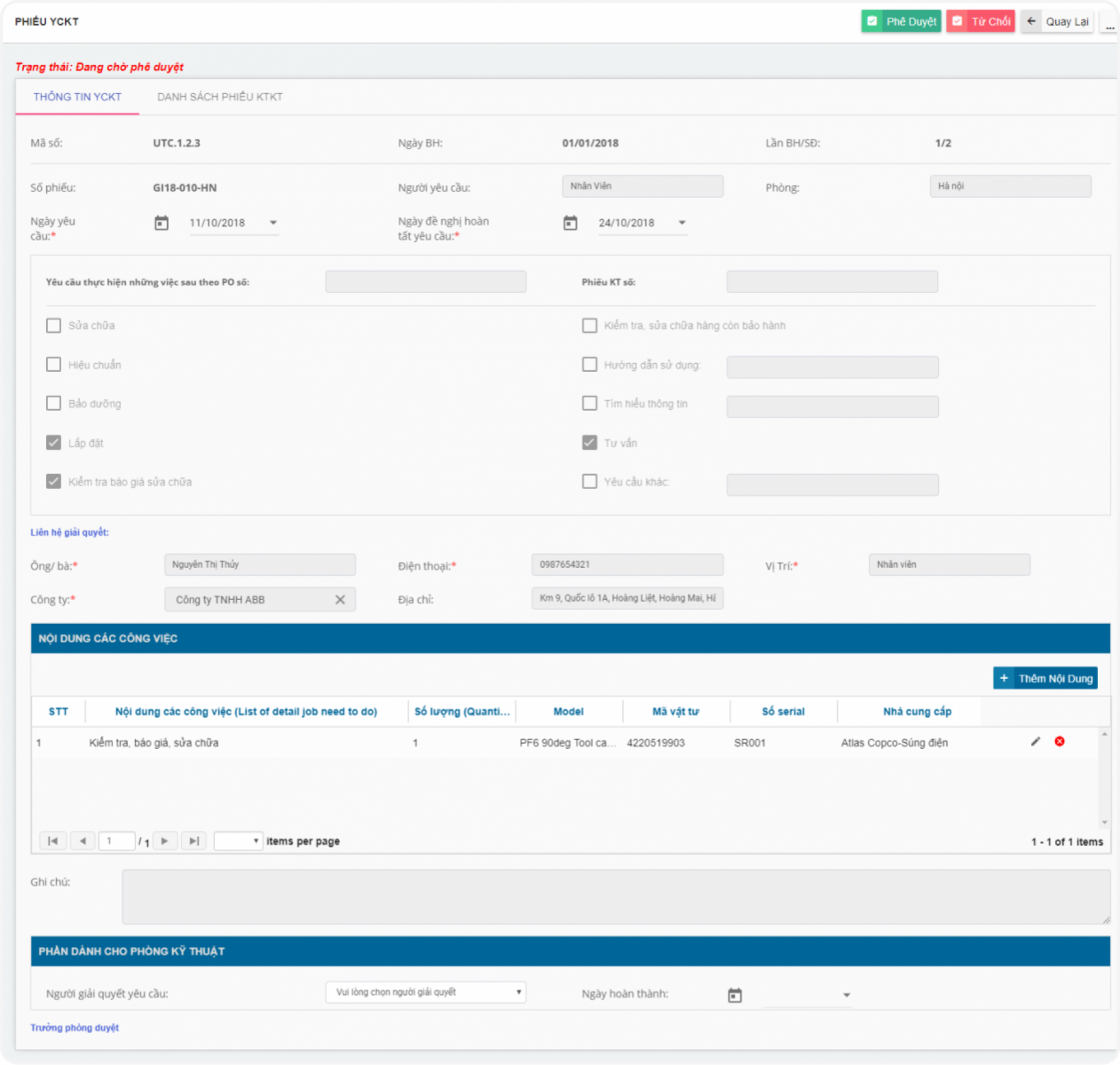

- There is a need for software to monitor and manage the process of maintenance, repair, and replacement of equipment sold or leased at customers.

- Automatic reminder of maintenance and repair schedules

- Processes and forms are in accordance with ISO standards applied at the enterprise

CHALLENGES

Tri Nghia's project team overcame many challenges to ensure a successful project:

- The information system about assets, equipment and accessories is very complex

- The process of proposing, approving and checking technical compliance with ISO process is very complicated.

- Customers do not have specialized IT staff, so the project implementation has difficulties in infrastructure

SOLUTION

- Thoroughly survey and confirm the customer's equipment/asset management process

- Collect and validate ISO forms in use

- Using Tri Nghia's existing platform to ensure project progress

- Consulting customers on IT infrastructure

TECHNOLOGY USED

- C# / ASP.NET MVC, SQL Server, Angular

RESULTS

- The project is completed on schedule, highly appreciated by customers and is being exploited very effectively (no errors in the warranty process)

- Software to help businesses change the way they provide services and take care of customers

- The software helps businesses to accurately monitor and evaluate the working efficiency of equipment maintenance and repair personnel.

SOME SCREENSHOTS

How can we help you? Drop us a line or two!

15+

years of experience

100+

great partners